When building cool rooms, freezers, factories, or commercial facilities, choosing the right insulated panel is essential for performance, safety, and long-term durability. At Precedent Insulated Panels, we supply and install industry-leading XFLAM, PIR, EPS, and Mineral Wool panels across Australia. Each panel type offers different benefits depending on your project’s thermal, structural, and fire requirements.

Below, we break down the key differences between each panel to help you make an informed decision.

Askin XFLAM

For projects where fire safety is a critical consideration, Askin XFLAM panels provide an advanced solution. These panels combine a high thermal efficiency with enhanced fire-resistant properties, making them suitable for commercial, industrial, and temperature-controlled facilities.

What is Askin XFLAM?

Askin XFLAM panels have a specially formulated core designed to improve fire resistance. They are tested to meet strict fire safety standards, providing reliable protection while maintaining the insulation performance expected from other panel types.

Key Features of Askin XFLAM Panel

- Enhanced Fire Resistance: XFLAM panels offer high fire ratings, reducing fire risk in high-priority environments.

- Thermal Efficiency: The panels maintain excellent R-values, supporting energy-efficient temperature control in cool rooms, freezers, and warehouses.

- Durability: Like standard insulated panels, XFLAM panels are resistant to moisture, warping, and long-term degradation.

- Broad Applications: Suitable for commercial and industrial buildings, cold storage, food processing, pharmaceutical facilities, and any project requiring elevated fire performance.

- See our Clean Room & Architectural Cladding Services: Architectural Cladding & Clean Rooms

Common Applications

- Cool rooms and freezer rooms

- Food and pharmaceutical processing facilities

- Industrial and warehouse buildings

- Any construction with strict fire safety requirements

PIR Insulated Panel

PIR insulated panels are one of the most advanced and reliable panel systems available, offering a strong balance of thermal efficiency, fire protection, and structural stability. At Precedent Insulated Panels, we install PIR panels for cool rooms, freezers, warehouses, food facilities, commercial projects and even passive houses where performance cannot be compromised.

The below section explains what PIR panels are, where they’re used, and why they are a premium choice for many industries.

What Are PIR Panels?

PIR (Polyisocyanurate) panels are manufactured with a rigid foam core that delivers excellent insulation and enhanced fire resistance compared to EPS. The closed-cell structure minimises heat transfer and moisture absorption, making PIR ideal for temperature-controlled environments.

Key Benefits of PIR Panels

- Superior Thermal Performance: PIR panels provide excellent R-values with minimal thickness, making them ideal for cool rooms and freezers where efficiency matters.

- Improved Fire Resistance: PIR offers stronger fire performance than standard EPS and is compliant with many commercial fire rating requirements.

- Durable & Long-Lasting: PIR panels maintain their structural integrity over time and resist moisture, warping, and degradation.

- Versatile Applications: Suitable for temperature-controlled rooms, food processing facilities, warehouses, commercial construction and even homes!

- See our cold storage and warehousing services: Cold Storage Warehouses & Distribution Centres

Common Uses

- Cool rooms

- Freezers

- Food processing facilities

- Pharmaceutical storage

- Commercial builds

- Industrial facilities

- Passive houses

EPS Insulated Panel

EPS (Expanded Polystyrene) insulated panels are one of the most widely used panel systems due to their affordability, versatility, and strong thermal performance. Ideal for cool rooms, dry storage, and general commercial construction, EPS panels remain a dependable solution for a wide range of industries.

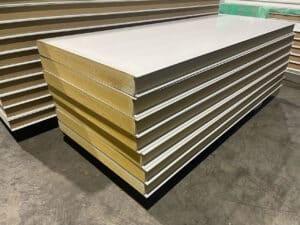

What Are EPS Panels?

EPS panels consist of a lightweight polystyrene core bonded between steel skins. They provide good insulation performance at an economical price point, making them a popular choice for builders, manufacturers, and cold storage operators.

Key Benefits of EPS Panels

- Economical and Efficient: EPS panels deliver excellent value without compromising performance, making them suitable for projects with budget considerations.

- Reliable Thermal Insulation: EPS offers stable and consistent insulation, suitable for cool rooms and temperature-controlled facilities.

- See our cool room services: Cool Rooms & Freezer Rooms

- Lightweight and Easy to Install: Their low weight reduces installation time and structural load requirements.

- Versatile Applications: EPS is used across commercial, industrial, and coldstorage environments.

Common Uses

- Cool rooms and chillers

- Dry storerooms

- Retail and commercial fit-outs

- Manufacturing facilities

- Internal partition walls

Fire Considerations

EPS has lower fire resistance compared to PIR and Rockwool. For projects with fire compliance requirements, consider Rockwool panels instead.

Mineral Wool Panel

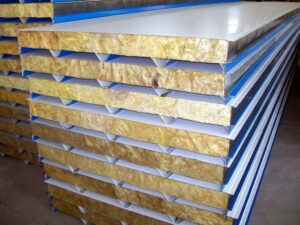

Mineral Wool panels are engineered for environments where fire resistance, acoustic performance, and structural durability are essential. Made from non-combustible stone wool, these panels are the industry standard for commercial kitchens, industrial plants, boundary walls, and high-compliance builds.

What Are Mineral Wool Panels?

Mineral Wool insulated panels contain a mineral wool core that is completely non-combustible, providing the highest level of fire safety available in insulated panel systems. They are often required under building codes for specific high-risk applications.

Key Benefits of Mineral Wool Panels

- Outstanding Fire Resistance: Mineral Wool panels offer FRL ratings suitable for fire-rated walls, boundaries, and industrial environments.

- Non-Combustible Core: Unlike EPS or PIR, Mineral Wool does not melt, burn, or release toxic smoke.

- Superior Acoustic Dampening: Ideal for noisy facilities such as manufacturing plants and commercial kitchens.

- Durability & Structural Stability: Mineral Wool panels withstand heat, moisture, and heavy use while maintaining performance over time.

Common Uses

- Commercial kitchens

- Fire-rated walls and ceilings

- Boundary wall construction

- Industrial facilities

- Mechanical and plant rooms

- High-risk manufacturing environments

- Acoustic environments

Need Help Choosing the Right Panel?

Every facility has unique requirements, including compliance, fire ratings, temperature needs, and structural considerations. Our team can provide guidance and turnkey installation for all insulated panel types.

Explore our services: Services

Contact us for a tailored consultation today.